A smokehouse is a place to smoke commercial foods.

|

|

I am writing this page in English with Google translator. Click the Danish version and see the original Danish website.

This English page is suitable for PC - Tablet - Mobile phone. |

The foundation is ready for casting The desire to build a well-functioning smoke oven has existed for many years. When I came across Peter Svendsen's article, "The best smoke oven you build yourself" in the magazine Do it yourself * 8/ 2002 May 24, there was not far from idea to action. The article was first published in magazine no. 8/1989, so one must say that the man was ahead of his time. If you go to the magazine's website, a subscription number is required to proceed with the search. You can log in by using your 10-digit subscription number as username and your postcode as password.

Outdoor kitchen under roof I have followed the instructions in the magazine on many points, but I have chosen that the smoke oven must remain in place and no smoke must come out of the joints. Therefore, the Isokern chimney caps are also fixed with mortar. It must be electronically temperature-controlled, so that I can smoke both summer and winter with the least possible difficulty. The smoke oven is placed at least 2.5 m from the boundary in a place so that it is prepared for cold smoke by making a separate firing point 2 m from the smoke oven. The "biggest" job, which brought sweat to the forehead, was digging the hole for the foundation. But it was also 25°C in the shade, and hard clay right down to the bottom.

The blue PVC pipe is for electric cables Here the foundation is ready for casting. The dimensions are 58x58x80 cm. There are 70 cm in the ground and 10 cm above. The blue PVC pipe must lead the electrical cables up into the oven. I'll get to that later. After a few days, the first two Isokern chimney caps are attached with mortar to the plinth and to each other. Remember no mortar on the side where the door should be. The two stack hinges were fitted to the right side of the oven, but not yet attached to the "door". Sawing is done at an angle of 45° halfway down the right side and the top stacking hinge is attached. Now saw all the way down and attach the bottom stack hinge. Masonry pegs 8x40 mm with spun screws climate-x 4x50 mm, Torx-25, and 4 board bolts for the square holes are used. The stack hinges are lubricated with 2-component epoxy. Just remember to remove feathers under the door.

Stacking hinges and brackets are fitted On the left side, the closing bracket and handle are attached. Before the closing bracket is mounted on the door, saw at a 45° angle all the way through according to the instructions in the article. If you do it this way, you are sure of a good result and things are more under control. I have chosen to build the smoke oven with 5 Isokern chimney caps, as the large trout and salmon are also to be smoked in the oven, not to forget the large silver eels and giant garfish that come in the autumn.

In this winter, everything is quiet

Then spring has come and I start again The oven is plastered with a very thin layer inside, so it must be done now that the first two Isokern chimney caps have been fitted. The next three Isokern chimney caps are installed and plastered as they come up. It is very dusty to file in pumice concrete, so use a face mask.

The "hat" with 5 cm insulation

Fitted with shut-off damper and jet hood All internal threaded rods are installed according to the instructions in the article, except for the two bottom ones. These are mounted a little further down, so that the top of the sawdust tray is flush with the bottom of the door. I have also chosen to put threaded rods in the two upper Isokern chimney caps. Then comes the "hat". I have made this in 12 mm waterproof plywood but in double height with 5 cm insulation (Rockwool or the white PVC) in the upper part. The feather of the upper Isokern chimney cap is removed with a chisel and filed flat. I used an old tuning iron. Contact adhesive is applied to the surface and to 3 cm wide rubber bands intended for sealing eternit roofs. It gives a close result. The "hat" is attached according to the instructions in the article, but for safety reasons I have chosen to put two extender brackets on the lid, as it is relatively heavy. I have polished the outside of the smoke oven for several reasons. Isokern chimney caps are very fragile, they cannot withstand pressure on the sides. They are very porous and absorb water, which must evaporate when heated. It requires energy. They are also not nice to look at in your garden. Later, I intend to paint the outside of the smoke oven so that it blends in well with the garden environment, or perhaps in a color that emphasizes the smoke oven. Interior paint is banned. I used a large lime brush and a thick slurry of cement and mortar for the exterior plaster.

August 2002 Easter 2003 A bimetallic thermometer is mounted 55 cm down on the front. It is made by Rüeger and ranges from 0 - 120°C. Bought from a plumbing installer. The valve is made of stainless steel and bought at a ship's supply store. The temperature control panel is built into the wall of the carport, so all cables can enter the box from the back.

Safety plate for falling objects A safety plate is required. It must catch the pieces that come loose from the suspension by accident during smoking and prevent them from falling into the sawdust and being destroyed. My safety plate of 39x39 cm is made of 1.4 mm stainless steel, it gives approx. 3 cm of air around the plate so that the smoke and heat can rise into the smoke chamber. My sawdust tray of 40x40x5 cm with heating elements and base plate rests on the two lower threaded rods. The sawdust tray is made of 1.4 mm stainless steel and with 5 cm high edges. Below this, two heaters are mounted in series for 230V and 3000W from a KGK fan heater. Each with a resistance of 17 Ohm. 6 mm threaded rods cut into 7 cm lengths and each provided with 4 nuts, washers and spring washers are used as spacers. You can see the new sawdust tray with the new heaters by "Click here".

Sawdust tray with attached heater and cover plate Remember ground connection on the plate with min. 4 mm screw, toothed washer and lock nut. Tube heaters for air heating see: JEVI A/S. |

Now the smoke oven must be fitted with a heater and electronics to control the temperature and air flowThe following cables are pulled through the blue PVC pipe: An installation cable 3x1.5 square with ground for 230VAC to the heater. A control cable for the electronics with three conductors for signal transmission from the temperature sensor LM35DZ. A control cable for the electronics with two conductors for the NTC resistor. A 12VDC supply cable for the fan in the box. And a temperature sensor from a digital indoor/outdoor thermometer, if you like. Check if all cables can be in the tube before you start. A 1/2" water pipe is embedded in the bottom of the oven so that any water can escape.

Kabler og 1/2 inc. vandafløb Postscript: In the picture above, the control cables for the temperature sensor LM35DZ and the NTC resistor can be seen going vertically up inside the smoke oven. It has now been changed so that they exit the smoke oven at the very bottom and vertically up the back wall, so they are protected against heat and mechanical wear from the sawdust tray and the safety plate. The fan at the bottom, which was originally from a PC, now needs to be replaced with a 230VAC version.

The fan at the bottom must be replaced A socket with earth is mounted at the bottom, and the sensor from the digital thermometer is placed inside the substrate. The socket is now mounted horizontally at the very bottom to give more space for the new sawdust tray. The temperature sensor LM35DZ, the NTC resistor and the skewer for the wireless frying thermometer are placed on the back wall 120 cm up from the bottom. On the outside of the back wall, waterproof electrics are mounted. boxes for cable connection. It is necessary if one or more sensors are to be replaced at a later time. See the pictures below. All cables inside the oven are routed in "Black Heat Shrink" tubing that is resistant to at least 135°C. The picture below.

Heat-resistant socket at the bottom A 40x25 cm Skamol plate is placed at an angle in front of the socket, so that it is protected from radiant heat. The digital thermometer measures the temperature in the socket and this will be approx. 40°C less than the temperature in the smoke chamber itself. The highest I have achieved in the smoke oven is 90°C. and 50°C in the socket.

Skamol plate for protection against radiant heat If you want a constant draft in the smoke oven with uniform smoke development, you must adjust the valve and the "hat" according to the wind. It can be done more "smart" by mounting a temperature-controlled fan in front of the valve in a small box, and mounting an adjustable shut-off valve with jet hood on the "hat".

The fan mounted in a waterproof box The fan is a 12VDC fan from a discarded PC. Pay attention to the current they work with - they are found between 120mA - 170mA. It works between 15V and 5V. When starting with a temperature of 15°C, the fan gets 15V and the voltage decreases almost linearly to 5V at 70°C, where it stops. It is connected to the temperature control, so there is both automatic control and manual control of the operation. If you want to see the calculations on the voltage regulation, then "Click here". Note: it is an Excel program. Rüeger thermometer eller Pförtner thermometer or Jørn Pedersen A/S

Rüger bimetal thermometer The shut-off damper can also be fitted with an on/off reversible motor, so that the exhaust can be regulated. However, the damper does not close completely, there is approx. 6% opening when the damper is closed. It seems to be very satisfactory.

Adjustable shut-off valve with jet hood Then it's lit up. The sawdust bin contains approx. 5 l sawdust. 1 l beech sawdust weighs 270 g when purchased (8% water content). The blend can be found elsewhere on the page. 1 dl of alcohol has been poured on the front edge of the sawdust and lit with a match, which is simply thrown onto the sawdust, then you avoid possible to be burned. After a minute, the door is closed, so there is fire in the sawdust.

Then the smoke oven is lit Postscript: I don't think it would be a good idea to mount a reversible motor, as the damper "soots" after many smokes. The motor cannot turn the damper. In addition, the water vapor must also come out of the smoking oven, otherwise the fish will simply be "cook" and this can also produce sour smoke. This is also called soot in a chimney.

Here you can see the 4 sensors inside the smoke oven The picture above shows the four temperature sensors that I use. From the top left, you can see the NTC resistor, the LM35DZ temperature sensor and the spear for the wireless frying thermometer. At the bottom, an additional LM35DZ temperature sensor. These are mounted respectively 27 cm and 55 cm from the top. Postscript: The location of these temperature sensors was later changed when an additional Isokern element was added on top of the smoke oven. All 3 temperature sensors are now 120 cm from the bottom.

The back with the 2 junction boxes for cables If you want to use two LM35DZ temperature sensors for different reasons - one in reserve or to switch between two heights in the smoke oven - these must be mounted with a switch in this way. No longer used. The sensors are built into a 10 mm stainless steel tube. The body of the sensors - NTC resistor and LM35DZ - stick straight out of the tube, which is filled with a 2-component epoxy. Do not use the one called "Super Quick" for the pipe, it hardens in 90 sec. Super Quick can be used as a layer on the sensors, so that they are protected against the aggressive environment of smoking. Version 1 and version 2 are no longer used, have been replaced by version 3

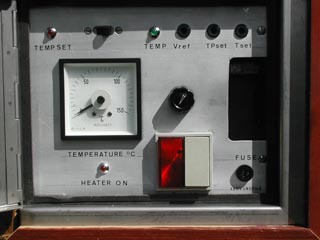

Electronic control panel version 1 The two Control Panels seen here are version 1 and 2. These were built into a stainless cabinet with a lock as they sat outdoors. The pointer instrument indicates the set temperature and the current temperature in the smoke oven using the slide switch just above. The temperature setting is made with the button in the middle. The main switch can be seen below. In addition, there is access to the main fuse and trimmer potentiometer from the front panel. The three LEDs indicate the set temperature, the current temperature and whether the heater is switched on (On). In addition, the switch has a red flashing light that shows that there is voltage on the system. A red lamp that can be seen from inside the house is mounted on the carport. It shows that the heater is "On".

Electronic control panel version 2, however without text The development of the smoke oven over 6 years

The picture is from 2002, when the smoke oven was finished ... but Over the years, many new things have happened, these are corrections to improve the smoke oven and of course new measures so that the smoke oven could become optimal. The first picture shows the smoking oven in 2002, where it has just been finished for the first smoking of herring and garfish that Mogens had caught in his net. I should just note that I had some break-in problems at first, so I had to fit an adjustable shut-off damper and jet hood in the "hat". Shut-off damper and jet hood were fitted, and the extra money was well spent, you can really control the smoke development. The price was approx. DKK 650.00

The picture is from 2008, when one more element was added Later I found out that the smoke oven was too short for eels, so an Isokern chimney cap came on. These covers must have some protection from wind and weather, otherwise they will crack in the long run. I came across a good offer for good quality tiles, so the smoke oven had to be lined with these. The hat was also remade so that the roof was no longer almost horizontal, but shaped like a pyramid. Now there are no drips from condensation on the fish. My neighbor - Mogens - does a bit of fishing in Køge Bay when the garfish come to shallow water

Herring and Garfish are cleaned and salted

I have just cleaned 4 rainbows from Karlstrup P&T Kringelbach's Salting and Smoking Book and Preben Madsen's Salting and Smoking

Here I can offer some good advice, buy from saxo or borrow from the library these two books: Kringelbach's Salting and Smoking Book and Preben Madsen's Salting and Smoking. You will find many good recipes. Go down and find these books on saxo's search engine and buy them by email. It's fast and cheap. |

Why do you salt and smoke your food? Conservation

A look at the garfish The fish were in the smoking oven for 3 - 4 hours, which Mogens thinks was too long. Hornfish and herring of this size only need 2 - 3 hours at a temperature of 65°C. Start temperature 80°C. for 20 to 30 min.

A look at the silver eels The picture above is silver eel, smoked for 4 hours according to the recipe found elsewhere on the website. As you can see, the eels are tied up with string. I used jute yarn 1.5 mm, No. 12129, breaking strength 25 kg, length of the roll 100 m, bought in Silvan.

Freshly smoked garfish Mogens, who has caught the garfish, assesses whether the smokehouse was successful. His comment was positive, but the fish needed a little less heat and more smoke. I used coarse-grained beech sawdust 7 mm. It would be better with fine-grained alder mulch, which we tested later. It gives more smoke.

Freshly smoked silver eel There was nothing wrong with the taste. If it weren't for the green legs, you'd think we were eating smoked eel. As for the smoked eels, they are no longer hung up with string. I now use a stainless steel hairpin skewer. It has been scrapped because the eels fell down if you stuck the spear through the backbone. The new eel hangers can be found just below. |

Block diagram of the electronic circuit for controlling the temperatureThe comparator has a 2x6 switch in the input, so that 6 different temperature ranges can be set according to your choice, also called Vref. I have chosen the range from 30°C to 80°C. The hysteresis function is achieved by a feedback from output to + input. A delta temperature of 1°C to 5°C has been chosen. The setting is made with P1. The comparator LM339 controls the transistor 2N2222A "On" "OFF" function. When the transistor 2N2222A is "On", the relay RLY1 is pulled and there is voltage on the heater and the red lamp. The hysteresis function has been chosen so that the relay does not stand and "clutter" because this can destroy the relay's plates.

Complete diagram of the Temperature Controller can be found here In this arrangement, there are no adjustments to be made, as the temperature range is determined by the voltage divider R6/R11 - R12/R17. But the values of the resistors must be followed and these resistors are metal film 1%. The temperature is read on a display LDP140LCD, which costs approx. DKK 120. It should be noted that this display must have its own power supply, which must in no way have the same ground point as the circuit the display measures. Therefore, the display also has its own transformer TR2. Relæ Switch for Actuator EURO 1

Relæ Switch for Aktuator - Actuator EURO 1 Component selection is again based on what I had lying in the drawer, as well as the purchase of cheap standard components. The actuator has 3 connections: Blue for neutral, Brown for phase (up) and Black for phase (down). If the phase changes between brown and black, the toothed rack moves up and down respectively. Using relay RLY1 it is very easy to change the phase. A control voltage of 0 V (Low) and 10 V (High) is connected to Vin. When Vin is 0 V, Q1 is off, and at 10 V, Q1 is on. The relay must work in time with the heater, so that the "hat" is down when the heater is on, and the "hat" is up when the heater is off. Control voltage comes from Temperature Controller IC LM339 Pin 2. Here is an example: The temperature is set to 70°C and the temperature in the smoking oven is only 60°C. On IC LM339 Pin 2 the voltage is "High", the heater is "On", the "hat" is down because Q1 is "On" and RLY1 is pulled with phase on black. Switches S1 and S2 are used for Auto/Manual operation Up/Down and On/Off. The PCB and built-in cabinet can be found here. If you use a 12 Volt transformer and a 7812 regulator, do not use R3. R5 and R6 are changed to 1.2K Ohm. But remember that there must be about 3 volts above a voltage regulator, so perhaps it can be omitted, as the circuit is not critical for small voltage variations. |

The new purchased temperature transmitter & receiverYou can now buy a wireless frying thermometer in Bilka for approx. DKK 130 on offer. It has a range of 25 meters in open air, and covers a range from -40°C to +200°C. There is also a High/Low alarm temperature setting or an indoor temperature reading. Can be converted to °C or °F. Of no importance to us in Denmark. The sensor is a skewer so it can be inserted into the roast, and the temperature can be measured in the ball grill or in the oven. A good buy, but REMEMBER not suitable for the microwave. I have built a 10 mm steel pipe into the smoke oven next to the other sensors, and here I just insert the new skewer. The transmitter cannot be permanently mounted, as it cannot withstand rain. Uses 5 pcs. AAA alkaline batteries for 6 months.

The new wireless frying thermometer bought in Bilka Diagram of temperature dependent fan

Calculation of the output voltage of the LM317. Web version og Excel calculation of the voltage regulation for Fan I have made a temperature dependent fan control for air intake. The reason is that I want to control the development of smoke and the heat from the embers in the sawdust regardless of where the wind is coming from. If the wind is SW, it blows straight into the valve and the sawdust glows more. If, on the other hand, the wind comes from the NE, there is almost no draft in the smoke oven. The reason for this is that the smoke oven is sheltered by the carport. With the switch S1, it is possible to supply the fan with power (On/Off). The new PSU for temperature dependent fan control is built into version 3 "Temperature Controller". The fan is built into a small 16 cm cubic box of waterproof plywood and mounted above the hole where the valve sat. Drawing of the box with air intake can be seen here. Holes are drilled in the bottom of the box for air intake. The voltage to the fan is regulated with an LM317 from 5V to 15V depending on the temperature. The NTC resistor is built into a 10 mm steel tube filled with 2-component glue, and placed in the smoke chamber next to the second temperature sensor LM35DZ. When starting at 15°C, the fan gets 15V and at 70°C 5V, where the fan can no longer run. The fan is from a scrapped PC with nominal operating voltage of 12V and a current of 170 mA. The original valve in the smoke oven has now been removed. |

Temperature regulator with built-in hysteresis in LM339 Comparator

Front panel for version 3 Temperature Controller for Smoking-Chamber

Front panel for version 3 Temperature Controller for Smoking-Chamber As I gain experience with my smoke oven, I am constantly trying to come up with new ideas to simplify the work process. A better and perhaps also a cheaper version of the temperature regulator with a temperature regulated fan is a requirement. Latest news is a "Linear Actuator" for opening and closing the "Hat". To meet these requirements, I have to return to the "Relay solution" and make a circuit with a Comparator with built-in hysteresis. Therefore, I have made a new construction of an advanced temperature regulator that can be set to switch off and on in a variable temperature range. There are 6 variable ranges from 30°C to 80°C. The six areas cover the following intervals:

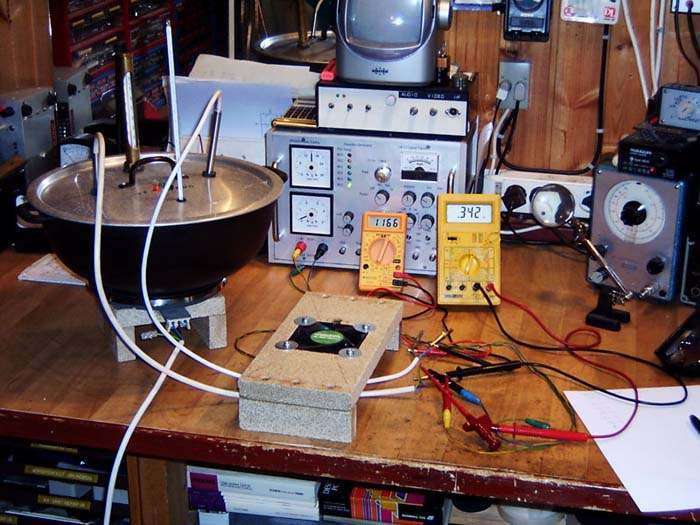

The delta temperature can be adjusted with potentiometer P1 from approx. 6°C to 1°C around the average temperature of the area in question. The chart above shows the 6 areas with the Delta Potentiometer P1 set to 5. Here you can read when the heater switches off and on. In the 30°C range, the heater switches off at 32°C and switches on again at 27°C. It is this function that is called hysteresis. If the Delta Potentiometer P1 is set to 1, the heater will switch off at 28°C and switch on at 27°C. But be careful not to go too far down, because then the relay may start to "clutter" due to the hysteresis function becoming too small. I never go below 2½, so there are no problems. A temperature table can be seen here. The whole "Glory" can be built into a Safty Box from Harald Nyborg with best. No. 3674 for DKK 178.00 or Bilka for DKK 179.00. Prices are from week 24 of 2004. The Safty Box can be seen here The diagram is a complete circuit for the LM339 with hysteresis for regulating the temperature in the smoking oven, as well as a circuit for temperature-regulated fan control. The temperature is shown on a 13 mm LCD display with background light. The output voltage for Fan is read on a 6 pc. LED voltmeter from 3 Volt to 18 Volt. The diagram and PCB lay out have been completed and the circuit must now be assembled and tested in practice. At the time of writing at the end of June 2004, the circuit has now "run" for a week with surprisingly good results. Knife-sharp switching on and off of the relay at the set temperatures. No arcing in the relay to destroy this. The delta temperature values ??hold all the way through, a very practical choice from approx. 1°C to approx. 6°C. The facilities that come on the PCB with the dimensions 200x150 mm are: Temperature regulator in 6 steps with hysteresis (delta temperature) and temperature regulated fan controlled in two ways. One via the temperature regulator, i.e. On/Off together with this. The other via relay for own mains supply, so that "cold smoking" can be done without the heater. I am not claiming here that it is cold smoking salmon at 27°C. But we'll see. Yes! just look here. I will come up with more descriptions and pictures as they are completed and I get time for this - there is also fishing to be done. If you didn't see my "little" workshop in TV Lorry, I'd like to show it here so you can see where the electronics and mechanics are made. It is not a chipboard, the hob and fan are mounted on, but a Skamol board. My homemade light box, which can be seen in one of the pictures, is in a chipboard box.

Here the Fan and Temperature sensor are adjusted.

The completed Temperature Controller is adjusted here |

How to smoke with spices smoke sawdust for eel

1 part juniper granules, 2 parts red elm crumble and 3 parts beech crumble My sawdust tray above can hold 5 l of sawdust, and with the new measures the smoking time is now 4 hours at 60°C - 70°C with good, constant smoke development. The sawdust mixture that I use for fish is composed of 1 part Juniper granulate, 2 parts Alder sawdust and 3 parts Beech sawdust. The mixture is distributed evenly in the tray and patted "a little" firmly with the hand. A few cl of alcohol are distributed along the leading edge in the sawdust and ignited immediately. The temperature in the smoking oven - this winter with minus 5°C - rose to 50°C in less than 5 minutes. After approx. After 30 minutes, the temperature stabilized at 70°C and smoke development was well under way.

Here you can see the finished smoked eel Here hang 17 eels with a total weight of 11 kg. They were smoked for 5 hours and cooled for 1 hour in the smoking oven, after which they were wrapped in Rul-Let Frostbox paper and put in the fridge overnight. That was then, but now I have a vacuum packer, so that's why they come in a vacuum bag and then in the freezer. The fish are now quickly hung into the smoking oven so that the temperature does not drop too much. The temperature is now selected on the electronics, and it stays at this temperature throughout the smoking period. If I want to smoke for a longer time, I have to top up with sawdust. A good piece of advice that can be recommended in winter is: When the fish is finished smoking, turn off the power, open the "Hat" a little and close the valve. Then let the fish "overnight" in the smoking oven until the next day. Juice and power, i.e. smoky flavor, accumulate in the fish, and it becomes very firm in the meat. Tested on eel, cod roe and trout . The council cannot be recommended in the summer period with a temperature of 20°C.

Then the rainbow trout are ready for the smoke oven The four rainbows were smoked for 4 hours at 70°C and "stayed" in the smoke oven until the next day. The night temperature here in April was 3°C outside and 7°C in the smoking oven, so it's still OK. The digital indoor/outdoor thermometer can also be used for this if it has a memory.

A look at the trout to see if they are ready

Four rainbow trout after 4 hours in the smoking oven at 70°C The four rainbows were smoked for 4 hours at 70°C and "stayed" in the smoke oven until the next day. The night temperature here in April was 3°C outside and 7°C in the smoking oven, so it's still OK. The digital indoor/outdoor thermometer can also be used for this if it has a memory. If it's summer, and you don't need to use all the fish here and now, you can wrap them well in Rul-Let Frostbox paper, again tinfoil. Put it in a freezer bag that closes with an elastic band so that it does not impart flavor to the other products in the fridge. Gives the same effect as mentioned before. New suspension method for eels. I have made hairpin spears from a 4mm stainless steel bar. Point both ends to. Pierced through the head from the dorsal side, but on either side of the backbone and under the two pectoral fins. Then the eels don't fall down.

I clean trout in my new Outdoor Kitchen If you want to please the lady in the house, build yourself an 'Outdoor-Fishing-Cleaning-Kitchen'. I just had a good space to build this kitchen on. By looking around the product, I found a stainless steel sink for a tenner (2 beers). Inlet water by a buried garden hose, connected with a quick coupling to the outdoor faucet solves this problem. It must be said that this arrangement is not frost-proof, but the outdoor tap is also closed in winter. In addition, the fingers also freeze with the minus degrees we had this winter. Postscript: Believe it or not, now the wife is so happy with this kitchen that she uses it to cook elderberry juice and beetroot in. My camping gas set does just fine, so we also get to use the rest of the gas from the summer fishing trip.

Now the trout are smoked and ready for packing

Quote: "Unfortunately, this is not the original website of the Friends of the Smoke Oven. The excellent website disappeared at the end of 2013. I don't know why. My great hope is that it is simply due to something technical and that the page will return". This is what the new Webmaster at Sundfisker writes about the friends of the smoke oven. Answer: The former Webmaster from the Friends of the Smoke Oven writes: "We - the Friends of the Smoke Oven were some old guys who just had fun together and that's why we started smoking the fish we caught and later others types of smoke too. But now there's only me (webmaster) left, unfortunately you don't live forever. Honor be to those you've been with". I have been very happy with the site: "Friends of the smoke oven" and used it a lot in the beginning when I started smoking my fish. We had also become friends and had "Link" to each other's websites. |

The new covered outdoor kitchen completed November 2004

The outdoor kitchen with tiles above the table My fantastic and lovely outdoor kitchen was finished in autumn 2003. When we got to the winter of December 2003, it was many times too cold, rainy with sleet and snow and whatever else came from above, to stand there and clean fish. That's why I chose to make my outdoor kitchen covered, so that I could at least be there in "dry weather" and sheltered from the wind. Some of the summer of 2004 went by.

The outdoor kitchen now has a sliding door At the same time, I also wanted to improve the possibility of an easier and more hygienic cleaning of the kitchen. I therefore installed tiles over the table. Naturally, lights and spots above the table also had to be installed in the ceiling. In addition, there is a square meter light panel in the middle of the ceiling. A short wall of 1 meter with a window has been put in the front to protect the fridge, microwave and freezer from the snow. Now I have every opportunity to grill and use my small smoke oven for small portions on the campfire, even in winter. Filleting a large home-smoked eel for packed lunches

Filleting a large home-smoked eel for packed lunches Here I show how to peel your smoked eel so that it looks good on a piece of food. Cut off the head first and remember the knife must be sharp. Then measure the eel and cut off as many pieces of 6 cm to 8 cm in length. The last bite of the tail is given to the cat. Cut off the top side along the upper side of the backbone. Cut along the underside of the backbone the lower side. Then cut off the skin on both pieces of eel. If necessary, trim the pieces of eel for skin and legs that "bring". The large eel used here was 63 cm and weighed 400 g after smoking. There were 5 good pieces of eel and the cat's tail. This way you always get nice pieces of eel, but remember to use a very sharp knife and the eel is best cut at refrigerator temperature. The eel meal is decorated with scrambled eggs and chives, seasoned with white pepper. Remember to taste the eel before salting.

Go to a printer friendly page At the same time as the outdoor kitchen was finished, I also had to build a footpath, as it would otherwise destroy the grass leading to the kitchen with all that traffic. Not to mention the footwear when it's winter with snow and sleet.

Newly laid brick path to the outdoor kitchen The new Temperature Controller was also fitted and tested under real conditions. It has really shown good results. Eel, garfish and trout have been smoked. The thermometer shows a temperature of 28°C in a 3 kg. sea trout to be cold smoked. One day I came across a cheap frying thermometer in Favør for DKK 50.00 and naturally had to try it out. The first test was in a hot-smoked sea trout of approx. 3 kg. The fish was filleted and the probe inserted into the thick end. After 3½ hours, the fish was finished and the final temperature in the fish was 41°C. I will come up with a complete recipe for the procedure as well as a recipe for serving the fish, as it is a heavenly dish.

Nice white smoke comes out of the Jet Hood Normally you shouldn't kick yourself in the rear, but I would like to show you how to light the smoke oven and use it without electricity. I use 8 to 12 small pieces of beech sticks placed in the bottom of the sawdust tray. The beech sticks must be dry and free of dirt or mold. You can buy these beech sticks where you buy beech dust for smoking. The beech staves split 2 to 4 times. Then put beech mulch once and pour 0.5 dl of alcohol on the leading edge. Light up with a match.

Lighting in a smoking oven without the use of electricity Let it burn well with the lid open and the hat open until the alcohol has burned away. Then close the lid and hat a little. Now you have to sit by the smoke oven yourself and check the temperature and the smoke development by opening and closing the door and the hat respectively. At 90°C you can put eel in the oven and at 80°C other fish. After some time - 30 to 45 minutes - the temperature should drop to 70°C. This temperature is tried to be maintained throughout the smoking period. Remember to add sawdust and beech sticks when smoking for a long time. I have used this method myself when I unexpectedly got eels for smoking and my heating elements had to be replaced and therefore they were not fitted. Try it yourself, it works flawlessly.

Lighting in a smoking oven without the use of electricity |

Here's the news: Cold smoking salmon and trout in my smoke oven

The perfect cold smoked trout Now it was time to test my smoke oven for "Cold Smoke". I had a large 3kg rainbow trout in the freezer which was suitable for a test. The weather on 23 March 2006 was perfect, high pressure, high sunshine, little wind and around 0 to 5°C. The fish was split and put in salt (3/4) and sugar (1/4) the day before. The fish "overnighted" in the fridge, because it was minus 5°C outside during the night. The smoking oven was prepared in the morning with sawdust in a 5 cm thick layer and 0.5 dl of alcohol was poured along the front edge. The alcohol was ignited with the lid ajar and the cap fully open. After approx. 30 minutes there was a good fire in the sawdust and the fire was "smothered" with a new small layer of beech sawdust. By adjusting the lid and cap I was able to keep the temperature between 25°C and 30°C. It should be noted that I did not use electricity.

The perfect cold smoked trout The fish came in at 09.00, after it had been rinsed of salt and the side legs cut off. The fish was then smoked at 27°C until 17.00. I refilled a few times with a thin layer of sawdust. The temperature was adjusted with the lid and the hat, so that you had to be over the fish all the time. The result is seen in the picture above. Delicious! See also cold smoked salmon. The new labyrinth sawdust tray with a drawing for making it

The new labyrinth sawdust tray. Click for drawing The new labyrinth sawdust tray is seen above, and a drawing for making the labyrinth sawdust tray is available by clicking below the image. At the bottom left of the hill in front, the sawdust is ignited with alcohol, and the embers propagate back and forth in the labyrinth to finally end on the right. When the fire has to be lit on the left side, it is because the door opens from the left and thus creates a draft in the oven from here. The tray is filled with sawdust approx. 8 liters or approx. 2.2 kg, but only up to 1 cm from the top edge, so that the embers do not spread over the labyrinth separation. I tried to cold smoke a 2.5 kg trout and the test ended with a good result for my Swedish sea trout. The smoking time was over 24 hours for the new tray, and the right compartment had not yet burned through after 24 hours. See a picture of the sawdust bin by clicking below the picture.

The new labyrinth sawdust tray. New eel suspension Result: The oven was switched on on Friday at 12.00 and At 12.30 the temperature had stabilized at 12°C. Outside temperature was 2 to 3°C at the time. For the rest of the day and throughout the night, the temperature in the oven dropped to 7°C, where it remained until the next day at 14.00, even though at night the temperature dropped to - 2°C. After I have tried to cold smoke a trout and especially with such a good result, I naturally have to come up with something new so that I don't have to run back and forth and close the hat up and down.

Actuator Mingardi Magnetic type EURO 1 I have found a reversible motor made by Mingardi Magnetic type EURO 1, which is used in large greenhouses to open and close the windows. The motor, which is actually called "Linear Actuator", is for 230 VAC and can lift with a force of 450 Newton. Converted to everyday speech, this corresponds to 45 kp. I just need the control unit, but of course I do that myself. My starting point is an up/down movement of 20 cm, which must be limited to 5 cm or 10 cm and a variable temperature regulation between 20°C and 80°C. The hat can be lifted with a force of 10 kp, which converted in the head is 100 Newton. So there is excess power available. (1 kp is equal to the weight of a 1 kg weight at 45° north latitude and corresponds to 9.81 Newton). Further information can be found on the page "Temperature control for smoke oven".

Actuator fitted with electronics for up/down control I have considered very carefully how to make my temperature regulator for this Linear Actuators. Should I make a completely new temperature controller, or should I simply connect the "Actuator" to the existing "Temperature controller". I chose to make a new one to try out all the glory. After this I could then decide what was best. The result was - until now - that I connect the Actuator to the existing "Temperature controller". I take the control signal from LM339 Pin 2, and lead this signal out from the box and forward to the front of the smoke oven, where I then connect a relay switch. This relay switch is built into the box seen in the picture above. Another 'problem' that had to be solved was that the "Actuator" could not be fixed outdoors, as it cannot withstand rain, but only slightly damp weather. Therefore, it was mounted on a 28 mm wooden board together with the electronics, which are mounted in a Teko Alutek AL12X box with the following dimensions 139.7x101.6x76 mm. The entire glory can then be mounted on 4 pieces. expansion bolts Ø 10mm L 100mm with wing nuts when it is to be used. The signal is taken from the 7-pole trailer connector, which is mounted at the bottom of the smoke oven, so connect 230 VAC and the Actuator is "ready to run".

The actuator at work Notice the red lamp in the background. When this is off, the temperature in the oven is above the set temperature and the hat then goes up. When the temperature falls below the set temperature, the heaters turn on and the hat goes down. |

An additional Isokern chimney element on the smoke oven

A new Isokern chimney element has been purchased The two top threaded rods were moved up into the new top. The 4 springs in the element were removed and the top sanded smooth before it was put in place. The new element was attached with tile adhesive and must then be plastered, like the "old" smoke oven. The 3 cm wide rubber bands are renewed and glued with contact glue to the new element. The "hat" is put in place and the hinges are screwed into the new element. Sealing tape is placed on the new base frame. Then the big eels can just arrive here in the autumn.

An additional Isokern chimney element is fitted The smoke oven is now fully assembled with an extra Isokern chimney element. Plastered inside and outside, and painted in the yellow color. The hat and the actuator are also mounted, and now it's lit up, so that the new thing can take color and get a "taste of smoke" before I start on the eels. I have tried cold smoking on a home-made cheese, which I would really like to turn into a real "smoked cheese". The sawdust was ignited with a little alcohol, and the temperature stabilized at 30°C after 1 hour with moderate smoke development. The heater was not on. After 2 hours, I took out the "Smoky cheese" and it tasted wonderful. Not much sawdust was used and smoke development continued at a temperature of 30°C, so I decided to hang two trout sides in the oven overnight. We'll see how they turn out. As in the picture of the cold smoked trout above. If the fish is to be really good, it should weigh at least 4 kg. Smaller fish get a little dry.

The smoking oven is now tiled The latest news here in the spring of 2009 is that I have tiled the smoke oven. I think it will be good, because now the chimney elements cannot draw water and thus crack in frosty periods. We will see. It holds. Silver eel Salmon and Trout Garfish Herring Mackerel Cod roe Smoked cheese |

The new hat with slanted sidesThe picture above shows the new "Hat" made of 15 mm waterproof X-veneer - purchased from Linå - with the dimensions 1220 x 800 mm for DKK 157.00 plus VAT and possibly shipping DKK 90.00 When the hat is completely made, painted and fitted with damper and jet hood, I will come up with more pictures. The drawings you can see here, then you can make your own hat. It is an Excel program. The four aluminum corners are attached to strengthen the hat. There is also self-adhesive aluminum tape that can be used. The purpose is mostly to prevent water from drawing into the joints. I have acquired some crystal clear polyethylene tube foil of 90 my for packaging the smoked eels. With a suitable welding device, it is now possible to weld the bags completely tightly. The air can also be sucked out of the packaging, but I heard from an "old" cook that you shouldn't do that with eel, because then the meat on the outside of the eel can take on a black color. It's a cosmetic thing that shouldn't affect the taste. I will of course try this myself before I start with this vacuum seal. See also the page Filleting of smoked eel Hover the "mouse" over the images below and they will freeze and you will have the opportunity to have a closer look. Model of the "Hat" made of soft masonite

The first model of the "Hat" I have made in soft masonite, so I could form some idea of how the "Hat" would look like.

The "Hat" made of 15 mm water-resistant X-veneer

Here is the "Hat" made of 15 mm water-resistant X-veneer. Nail and screw holes filled with plastic wood, and made smooth with sandpaper. Ready to first time painting. I've been using ubiquity, Swedish Red træfix from jem & fix.

The "Hat" is painted and the corners are reinforced

The corners are reinforced with 0.6 mm aluminum rails, bought in Bauhaus for DKR 80.00. The rails must naturally be adjusted the "Hat". You can easily cut them into shape with a shears. Glued with contact glue and each have 6 pieces blue nails. There are also self-adhesive aluminum tape, which will surely do as much good. The purpose is only to prevent water entering the joints.

The "Hat" mounted on Smoking Oven

The "Hat" is fitted with the old hinges and of course the old Jet Hood with dampers.

The actuator is mounted on the Smoking Oven

The actuator is mounted on the Smoking Oven. The opening is now larger than before because of the bracket sits farther down. Should it be changed, the actuator must be moved farther down the board. We'll see. The location is OK.

Here is the first eel smoked with the new "Hat"

The first eel smoked in the new "Hat" was smoked a day with a huge low pressure with strong gales and rain. The rain fell directly into the Jet Hoodn and gave black stripes on two eels. Apart from this, all eel was perfectly smoked. A new evaluation must occur at a different and better time.

A little about temperatures up through the Smoking Oven

The picture above shows the temperature 85°C in the Smoking Oven with a wireless roast thermometer at the receiver located in the office. It should be noted that the device shows around 10% too much because of a faulty sensor.

Here is the transmitter of the roast thermometer located

The transmitter also shows 85°C. Actual temperature approx. 77°C.

Output temperature from the Jet Hoodn

Output temperature from the Jet Hood measured with a standard glass thermometer and shows 65°C.

A roast thermometer into the largest eel

I put a roast thermometer into one of the biggest eel from the anal and down through the tail. Eels finished tender when the temperature shows 67°C in the flesh. The thermometer shows here 51°C. The eel weighed 990 grams after smoking.

The old bimetal thermometer on the front

The old bimetal thermometer on the front of the Smoking Oven is closest sawdust tray and shows 78°C.

The temperature at the bottom of Smoking Oven

A thermometer shows that there is 71°C at the bottom of Smoking Oven. The high temperature caused by radiant heat from the heater.

Master Temperature Controller

Here is the Master Temperature Controller that controls the temperature and actuator. The sensor is located in the middle of Smoking Oven, and should then show a mean temperature. Here is 75°C.

The new bimetal thermometer

In the new Isokern chimney cap, I put a bimetal thermometer. It shows here 64°C. The slightly lower temperature might be due to an eel touches the sensor. Be careful with this.

An overview of all thermometer

At the top is glass thermometer in Jet Hood. To the right is the wireless thermometer and transmit in to the office. Left at the top is the new bimetal thermometer. Beside the actuator is the roast thermometer, which measures the temperature inside the eel. Middle of the front is the old bimetal thermometer. The temperature sensor to the Master Temperature Controller is on the back wall in the same height as the old bimetal thermometer. Bottom left is the thermometer that measures temperature at the bottom of Smoking Oven.

It is not meant that You must have all of these thermometers in your Smoking Oven. But I think there should be two at least. A measuring temperature in the center of the eel. A measuring temperature of the output smoke from the Jet Hood. Final remarkIn the early phase of smoke, where eels are wet, there is much water vapor that must come out of the Smoking Oven. Therefore, there is a large temperature difference up through the Smoking Oven. This temperature difference becomes smaller when the eels are done smoked. You can use the two thermometers to shows this temperature difference.

New 2000 Watt heating element mounted

After several years of operation the old heater did not work anymore. The insulation between the heating wire and sheath melted away, and therefore gave short circuit to protection ground. On the Web, I found a new 2000 Watt heating element for DKR 295.00 used for a Blomberg convection ovens. If the heater can handle the job, should of course be tested.

Underneath the sawdust tray fitted a new 230 V fan ripped from a heat gun. It is necessary to transport the heat up and away from the heater. I will give more news when it is tested for some time. The new heater and fan has now worked flawlessly for a year, so it is recommended to use these two parts. |

My friend Thomas has made a wood smoke oven in the same dimensions as my smoke oven in Isokern elements

Wood smoke oven that Thomas has made Thomas has made his wood smoke oven in the same dimensions as my smoke oven in Isokern elements. When I moved I sold my actuator to Thomas and I fitted it for him. He then suggested that we could smoke together and we have now done that for several years.

I have now installed the Actuator and we are sitting and enjoying a cold Pilsner Since the smoke oven is made of wood, you can't have the hearth inside the smoke oven, so Thomas bought a small, used wood stove that could be left outside. It was connected with a 2 meter cast iron pipe to the smoke oven. It "works" just fine. We can now cold smoke with a spiral at the bottom of the smoke oven and hot smoke with the small wood stove. It makes a fantastic cold-smoked bacon and good hot-smoked eel.

Wood smoke oven with cast iron oven for hot smoke Here we are working with cold smoked bacon. My fishing buddy - Bent - has also joined the pit. We smoke eel, trout, salmon, bacon and duck breasts together. It is a good idea to fill up the smoke oven if you want to be price-proof.

The smoke oven is tested with bacon My Gastromax food salt strainer for 1 kg of smoked coarse sea salt. Sieve Ø 19 cm bought in Bilka. The chain 2 meters and 2 hooks bought in jem & fix. I had the three key rings in the drawer. A total of DKK 133. I hang it in the smoke oven when there is a free "lane", so I can use the excess smoke.

Gastromax food salt strainer for 1 kg coarse sea salt Thomas has had a Pizza Oven for several years, but it was "stored" in a barn and was not used. When I saw it, I gave Thomas the good idea that it should be restored and put into the room with the smoke oven. It was not so easy, because the oven weighs around 800 kg. But with the help of a good neighbor with a forklift, it succeeded, although not without "crossing". The pizza oven split across right across the middle. You can see it in the picture just above the door - a strip filled with heat-resistant cement. As the good craftsman Thomas was able to fix it with "ease". Now we are writing in the middle of October and it is time to smoke eels, therefore we must also inaugurate the Pizza Oven, so that we can have another round of bread while we wait for the results of the smoked eels. There will be pictures of our homemade pizzas later.

Now the new Pizza Oven is ready for inauguration in October 2022 Here is one of the first pizzas we baked in the oven. Bent made the delicious pizza topping and I made the pizza dough. We made it at home the day before for practical reasons.

Here is one of the first pizzas we baked in the oven Back to the page you came from. |

one.com |